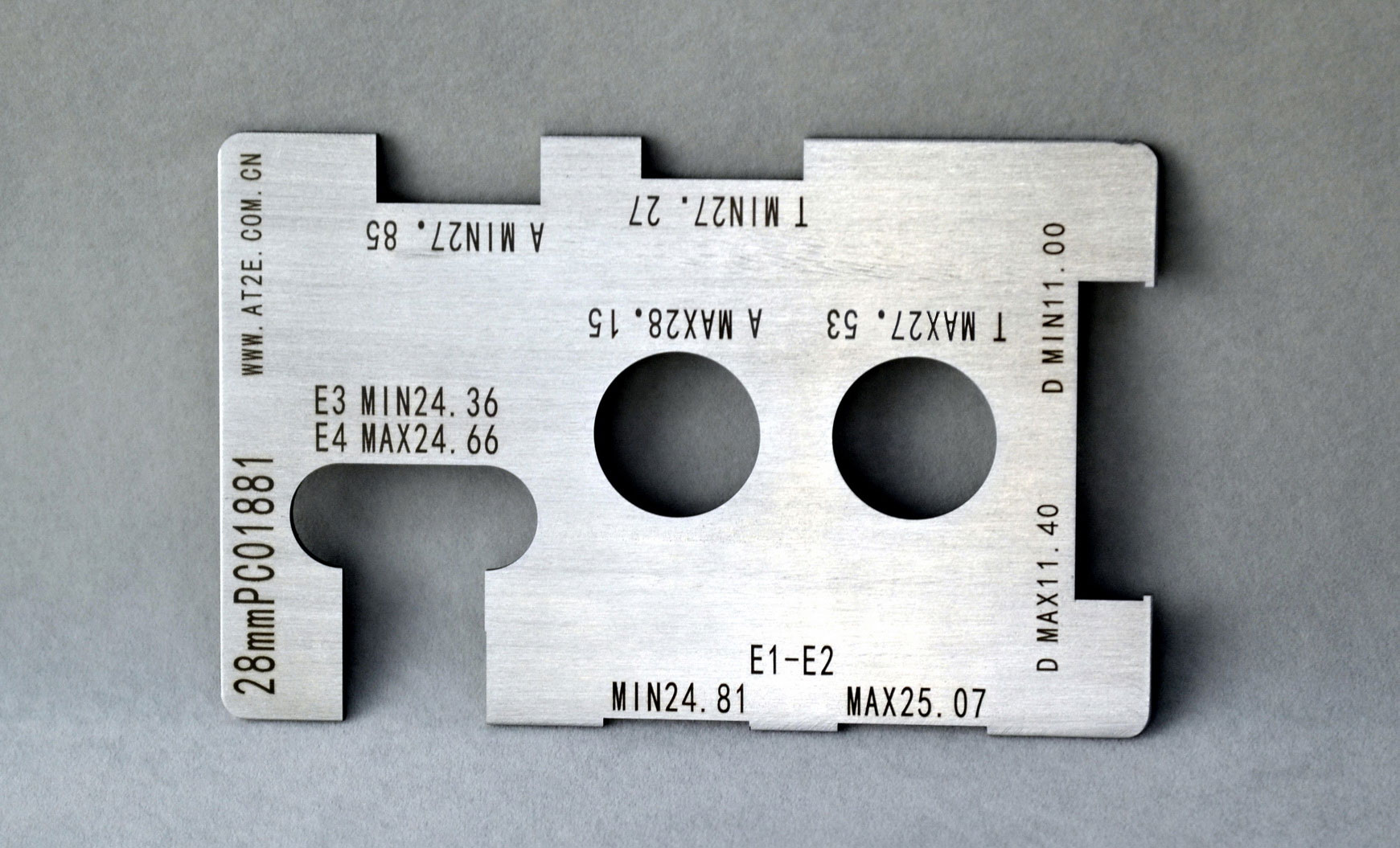

In order for the chamber to be in-spec, the bolt must close without resistance on the go gauge, but it must not close completely on the no - go gauge. In addition, there is usually a third gauge called FIELD that is slightly larger than the no - go gauge. Go - No Go gauges are manual mechanical measuring tools used in production lines to guarantee the machining has taken place and it has been performed correctly.

There are two types: plug-shaped for internal round holes fork-shaped for external diameters, ring-shaped for. Go No - Go gauges are inspection tools used to determine if parts are manufactured within specified tolerance limits. As the name suggests, A GO gauge is intended “to go ” inside the part feature being tested and it is manufactured with maximum material condition. They may measure a physical dimension, e. A typical example is a plug gauge.

For small threaded parts, the gauge will be double ende with one end carrying the GO gauge and the other en the NO - GO. For large parts, the two may be separate pieces. Target-Size Plug Gauge Sets Get your choice of one target-size gauge with larger gauges and smaller gauges, graduated in 0. Plug gauge is used for the assessment of the hole or diameter of an object. GO and NOGO Gauge Free Preview Plain Plug Gauge.

Behalf of checking the diameter plug gauge also use in comparing, setting, calibrating of other gauges. Go no go gauges, also come in both non-threaded smooth variety, such as a pin gauge, or threaded versions which check threaded connections.

Also known as Go - No - Go Gauges. Use these gauges for inpection of pins for corect grip length after installation. This Go-No-Go Gauge is designed for use with the AFand AFMCrimp Tools from DMC. Over time and repeated use a crimp tool can eventually lose its accuracy or get damaged and have its tolerance changed.

Usually the changes are minimal and acceptable, but sometimes the slight change in calibration can be outside or acceptable tolerances. Convenient kits contain “ Go ” and “ No - Go ” gauges for accurately checking chamber length to make sure it meets SAAMI specs.

These gauges are essential tools for ensuring a tight, accurate, safe chamber when chambering a new barrel. The Go and No - Go principle of gauging is that the Go -end of the gauge must go into the feature of the component being checked.

The No - Go end must not go into the same feature. The dimensions of the Go and No - Go ends of gauges are determined from the limits stated on the dimension of the component to be gauged. Pin Gauge is used to check the position,size of hole, distance between two hole,and the deep of hole.

It is necessary instrument for checking precision cast. Pin gauge is widespread used for. Forster Headspace Gage. It does not return a size or actual measurement in the conventional sense, but instead returns a state, which is either acceptable (the part is within tolerance and may be used) or unacceptable.

Go and No Go Gages are typically simple devices like Go and No Go plug gages, Go and No Go ring gages or Go and No Go Snap Gages that contain no moving parts and are easy to use. As such, their use is very common. Go and No Go gages are also easily portable, do not suffer breakdowns in service, and typically do not require power. I was told I need to get my Mchecked with a Go-No Go gauge.

Here is a Large Go gauge in a known good 308: Here is the same brass with a no - go gauge : If the tool was to go into the primer pocket, you know it is too large and brass needs to be tossed. The NOT- GO gauge would be in the form of snap gauge or Gap Gauge, so that it is able to reject the non-circular shaft as shown in Fig.

Non-Circular Holes and Shafts: According to the Taylor’s principle (for checking non-circular holes and shafts) the GO - Gauge would be of course be of full form, corresponding to maximum metal condition of the part. GO NO GO thread gauge is thread inspection tool for checking thread.

NO GO end should be stopped between the thread of work-pieces. If not like so, then we can judge that the thread of work-pieces are not well enough. Thread gauge GO NOGO is measuring tool for checking tool.

This flat piece of rectangular metal, with circular cutouts side by side, helps you by ensuring your crimp’s fitted correctly. The ” Go ” side is where if your crimp goes over the ring easily, the crimp is correct.

The ” No - Go ” side is just that, the crimp ring isn’t able to go through at any point. Installation notes: Simply put this gauge in your chamber and close the bolt (action). Everything should lock up around the GO gauge. The bolt should fail to lock up around the NO GO gauge.

GO are identical items so if you were planning to get one of each you only need one. The no - go plug gage (minus tolerance) would represent the maximum diameter of the product tolerance for the hole. The sum of the go and no - go gage tolerances should not equal more than 10% of the total product tolerance (the 10% Rule).

The go gage is fairly straightforward. Point here, is the go gauge and tape work - for the folks that have done a few (bunch for some) barrel changes can see that using a case would work - comes down to a little common sense and trusting what ya know.

The gauge is used for checking if a crimp has been properly done. If the go-no-go gauge fits over the crimped ring it is crimped properly.

Nessun commento:

Posta un commento

Nota. Solo i membri di questo blog possono postare un commento.